Plaque Styles (Overview of Materials and Design Features)

Welcome to our overview of the various choices of design styles you have for our wall and podium plaques. We make a wide variety of wall plaque styles with different materials, carving techniques, surface coatings, and design features.

The carved 3-D bas-relief, 2.5-D multi-level flat relief, and engraved plaques we manufacture have substrates made of either High-Density-Urethane (HDU), long-lasting weather-resistant softwoods such as Western Red Cedar or California Redwood, or beautiful hardwoods such as African Mahogany, Cherry, Walnut, Maple and Oak. We also offer cast solid bronze and aluminum 3-D nas-relief and 2.5-D flat-relief plaques (highest prices) , and thin acrylic 2-D plaques with digitally printed appliques (lowest prices). We employ several types of surface treatments including artist painting and clear-coating, staining and clear-coating (wood only), digitally-printed giclee full-color appliques, metal-plating, metal polishing and burnishing, gold & silver-leaf gilding, and cut-out aluminum cladding for raised flat art and letters.

We use only the finest materials (and highest cost) and craftsmanship to make our beautiful plaques, so you can be proud of them while they continue to look like new for a lifetime.

You are always welcome to call Christie or Regina at 951-698-8484 or you can email us at info@artsignworks.com to get more information, to describe a plaque you want made, or to get prices.

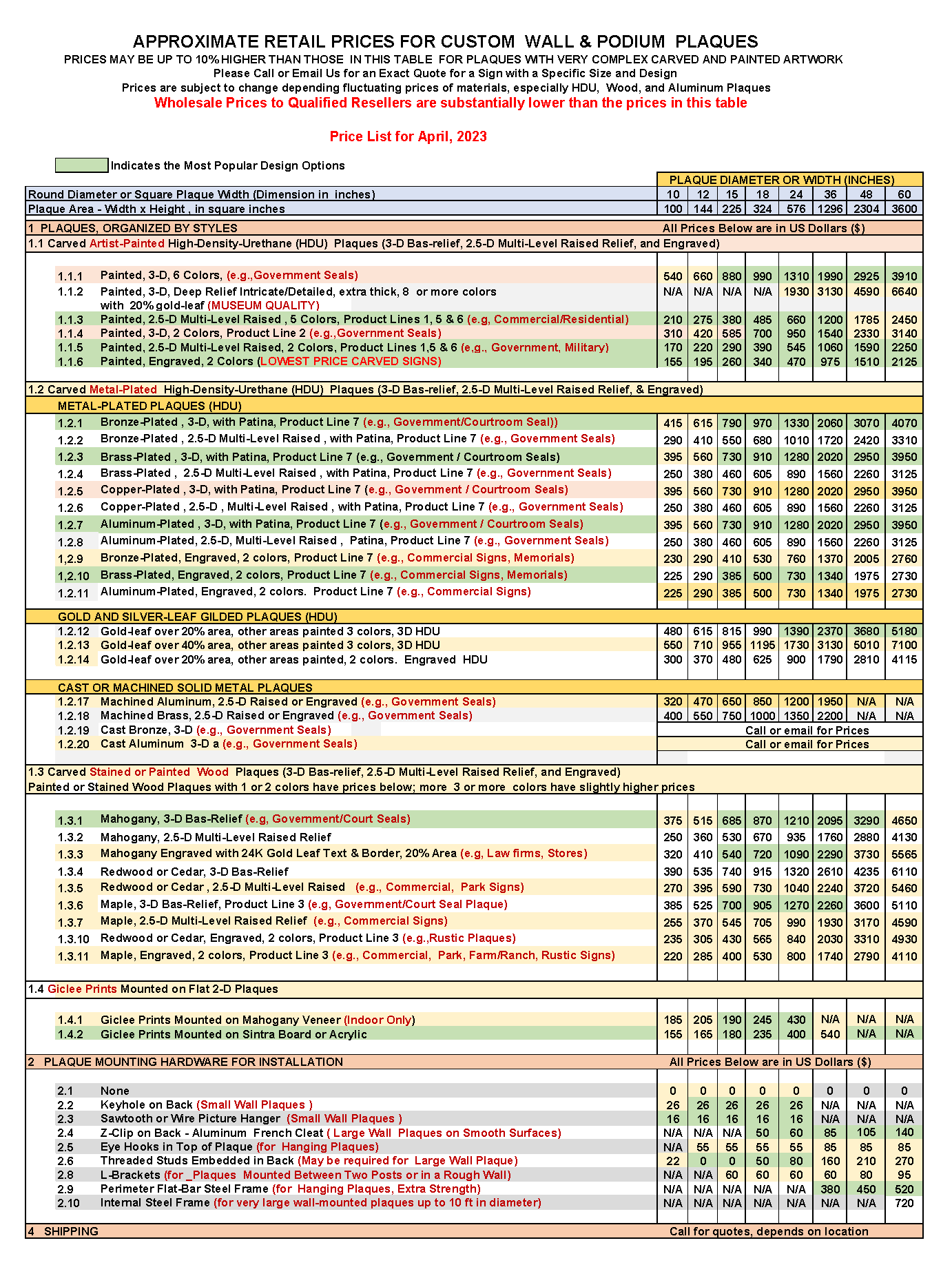

1. PLAQUE STYLES AND THEIR PRICES

The price of a plaque is based on its style and its size (its diameter, if round, or height/or width, whichever is greater). Large plaques have higher prices than small plaques, wood plaques (Style Category 1.3 below) are more expensive than High-Density-Urethane (HDU) plaques, because wood material costs about twice as much as HDU, and takes more labor to carve and sand. Metal-plated HDU plaques (Style Category 1.2 below) have higher prices than painted HDU plaques because of the high cost of the metal plating (especially 24K gold leaf) and the labor to polish and burnish the metal to a high shine. 3-D bas-relief (i.e., rounded surface profiles, like Greek friezes) plaques have higher prices than 2.5-D multi-level flat relief or engraved plaques, because they take 3 to 5 times as long to carve, and it takes 2 to 3 times as long for the artist to intricately paint them with many colors with a small artist brush. Our least expensive dimensional plaques are 2.5-D flat relief or engraved HDU plaques with one to three colors, because they can be made with only a few hours labor. Our least expensive plaques overall are in Style Category 1.4 (Economy Plaques, with giclee printed artwork and text ), because both material and labor costs are much lower for than our carved dimensional plaques. We give discounts of 10% to the prices listed below if 3 or more identical plaques are ordered at the same time. Fig. 4 below shows a summary price list for our most popular round plaques. A more comprehensive price list is given on our PRICE page.

Our plaques have wide variations in prices, depending on size and style. Fig. 2 below shows our three basic relief styles, 2-D flat relief , 2.5-D multi-level relief, and 3-D bas-relief. These can be made of different materials, including natural wood, artist-painted High-Density-Urethane (HDU) , metal-coated HDU, and acrylic. Our STYLE page describes these in detail. Most of the 5000 photos of plaques on this website has a Style Category listed in the second or third paragraph in the text description under the photo (click on the photo or title to expand the photo and read the text to get the price code of that plaque, then look up the price for different size plaques with that style on the Price List at the bottom of the PRICE page).

2-D Flat Relief. Our lowest price economy 2-D plaques feature digitally-printed full-color giclee vinyl appliques mounted on a round or rectangular a solid wood or acrylic base. The retail prices for this type of two-dimensional (2-D) flat custom plaque are as low as $110 (Sintra base) to $140 (Mahogany solid wood base) for 10 inch diameter plaques. The same style plaques in a 18 diameter size have prices of $170 (Sintra) and $190 (Mahogany veneer). We also offer a matched set of the five armed forces seals in these styles at a 10% discount. These low prices assume we have made a previous plaque of the same artwork design ( featured in one of our Galleries of over 2000 photos, including photos of 3-D plaques), or for new artwork, that we are provided a print-ready JPEG photo or colored drawing of the artwork for the plaque. These are styles 1.4.1 ( Mahogany veneer base) and 1.4.2 (Sintra or acylic base) on our PRICE page, with examples shown on our 2-D Giclee Plaque web page.

2.5-D Carved Multi-Level Raised or Engraved Relief. Our carved 2.5-D multi-level or engraved hand-crafted and artist-painted plaques have prices about twice that of the 2-D flat plaques with giclee printed art. These prices depend on the size, material, carving complexity, and number of colors. Prices for custom carved 18 inch diameter 2.5-D artist-painted HDU. metal-plated or stained wood custom plaques vary from $270 to $420. Prices increase with size. The PRICE page gives prices for carved 2.5-D plaques of various sizes, materials, styles, and number of colors. About 80% of our round plaques are carved in 2.5-D multi-level flat or engraved relief, using High-Density-Urethane (HDU) as the substrate. These are very popular and look great. Many times the artwork provided to us for custom military plaques does not benefit from 3-D rendering, and we recommend a 2.5-D relief carving which looks nearly as good and is about 2/3 the price. Our 2.5-D relief plaques carve faster and are much faster to paint than 3-D bas-relief plaques, so they have lower prices. Most of our military and many of our government, university and corporate plaques are carved in 2.5-D relief.

3-D Carved Bas-Relief. Our premium plaques are carved in 3-D bas-relief, using wood (usually Mahogany, Cedar, or Redwood), or High-Density-Urethane (HDU) as the substrate. These are higher-priced carved 3-D bas-relief artist-painted plaques, and have prices about 3 times that of the 2-D plaques. These are very high quality plaques, which usually feature great seals, and are often ordered by higher level commands in the military services, federal and state government agencies and courts. Prices for 18 inch diameter 3-D artist-painted or bronze, brass or silver-plated HDU or stained wood custom plaques vary from $500 to $700. Prices increase with plaque size. Fig 4 below and our PRICE page gives prices for carved 3-D plaques of various sizes, materials, styles, and number of colors. These high-quality plaques may require from 8 to 24 hours of machine carving time, and then 6 to 8 hours of artisan work to hand-sand and artist-brush paint or metal polish them. They are unique works-of-art for our most discriminating clients.

Small 3-D Printed Statues, Sculptures, Plaques and Signs. We also make small 3-D statues, sculptures, and plaques, up to 10 inches high or wide, with our 3D Printers. These include 3-D printed in full relief, half-relief and bas-relief and are made using PLA, a commonly used thermoplastic material which is strong and tough. These can be artist-painted or plated with bronze, brass, aluminum or copper metals. They are elegant, beautiful, and add interest to any sign or plaque. These can be used as small indoor decorative statues, desktop or small wall plaques (up to 10 inches in diameter), or 3-D appliques on large signs or command/award boards,. These typically cost $100 to $200.

Chain-of-Command , Award and Recognition Boards & Plaques.. We have not listed approximate prices for chain-of-command , award and recognition plaques because pricing for these is complex with many variables, including size & material of the plaque, the number and size of replaceable photo frames and engraved brass plates, the number of 3-D carved appliques, etc. These typically range from $500 for small simple perpetual plaques to over $5000 for very large Mahogany 5 ft x 8 ft command or award boards. Call us at 951-698-8484 or or email us at info@artsignworks.com for an exact quote.

Fig 2 - We make plaques in three different carved styles of relief, as shown above. Engraved (recessed text and art) plaques are in the same price category as 2.5-D raised relief plaques. Prices increase from left to right.

2. STYLE CATEGORIES AND PRICE CODES

The Style Categories for all our style categories are listed in the table below. Actual prices for all plaques are listed in the table in our PRICE page, for various sizes of plaques. Each of the styles below has a digital number (e.g., 1.1.3) . Every plaque shown on this website has a Style Code immediately under its photo in the expanded view (click on a photo or its title to get an expanded view and description of the plaque). That style is described in one of the style pages (click on a gold underlined link below and or on its name in the pull-down menu under STYLE in the gold masthead). The price of that plaque is given on our PRICE webpage. Click on the underlined gold text to go to that Style Category page which provides a more detailed description of that style.

STYLE CATEGORIES AND PRICE CODE LIST

1.1 Style Category Carved and Painted HDU Plaques

- 1.1.1 Painted, 3-D, 4 or More Colors

- 1.1.2 Painted Intricate & Detailed 3-D and Painting

- 1.1.3 Painted, 2.5-D or Engraved, 4 or more colors

- 1.1.4 Painted, 3-D, 1 to 3 Colors

- 1.1.5 Painted, 2.5-D or Engraved, 1 to 3 Colors

1.2 Style Category Metal-Plated and Cast Metal Plaques

- 1.2.1 Bronze-Plated, 3- D

- 1.2.2 Bronze-Plated, 2.5-D or Engraved

- 1.2.3 Brass-Plated, 3-D

- 1.2.4 Brass-Plated, 2.5-D or Engraved

- 1.2.5 Copper-Plated, 3-D

- 1.2.6 Copper-Plated, 2.5-D or Engraved

- 1.2.7 Nickel-Silver or Aluminum-Plated, 3-D

- 1.2.8 Nickel-Silver or Aluminum Plated, 2,5-D/Engraved

- 1.2.9 Gold-Leaf Gilded 3-D HDU (40% of Area)

- 1.2.10 Gold-Leaf Gilded 3-D HDU (20% of Area)

- 1.2.11 Gold-Leaf Gilded 2.5-D / Engraved HDU (10% Area)

- 1.2.12 Gold-Leaf Gilded 2.5-D / Engraved Mahogany (10% Area)

- 1.2.13 Silver-Leaf Gilded 3-D HDU (40% of Area)

- 1.2.14 Silver-Leaf Gilded 3-D HDU (20% of Area)

- 1.2.15 Silver-Leaf 2.5-D /Engraved (10% Area)

- 1.2.16 Cast Bronze 3-D

- 1.2.17 Cast Bronze 2.5-D or Engraved

- 1.2.18 Cast Aluminum 3-D

- 1.2.19 Cast Aluminum 2.5-D or Engraved

1.3 Style Category Carved Natural and Stained Wood Plaques

- 1.3.1 Mahogany, 3-D

- 1.3.2 Mahogany 2.5-D/Engraved

- 1.3.3 Cedar or Redwood 3-D

- 1.3.4 Cedar or Redwood 2.5-D/Engraved

- 1.3.5 Cherry/Maple/Oak 3-D

- 1.3.6 Cherry/Maple/Oak 2.5-D/Engraved

1.4 Style Category Economy Plaques (Giglee Printed 2-D Plaques)

- 1.4.1 Giclee Plaques with Wood Base

- 1.4.2 Five Armed Forces Plaques Wood Base

- 1.4.3 Giclee Plaque with Acrylic Base

- 1.4.4 Five Armed Service Plaques Acrylic Base

1.5 Style Category Command and Award Boards and Plaques

- 1.5.1 Chain-of-Command and Organization Wall Plaques and Boards

- 1.5.2 Award and Recognition Wall Plaques and Boards

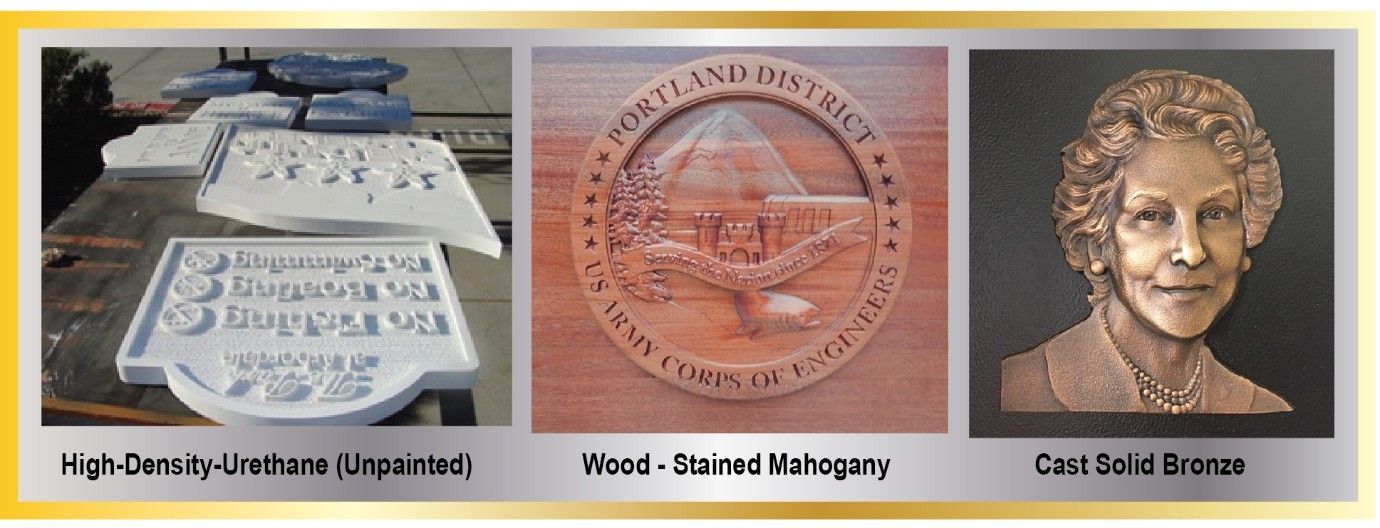

Fig 3- The three most popular general styles we use for our Wall and Podium Plaques are shown above - artist painted (Style Category 1.1) , metal-plated (Style Category 1.2), and natural/stained wood (Style Category 1. 3)

Fig 4- The table above gives an abbreviated price list of our smaller, most popular round plaques. The full price list is given on the PRICE webpage.

The remainder of this page describes various design features of a plaque that defines its Style. Section 3 describes our various substrate materials (HDU, metal and acrylic). Section 4 describes plaque shapes and sizes. Section 5 describes carving relief profiles (2-D, 2.5-D, 3-D, and engraved). Section 6 discusses our surface finishes (paint, metal-plating, stain, clear-coating, and giclee prints), and Section 7 describes methods for mounting plaques on a wall or podium.

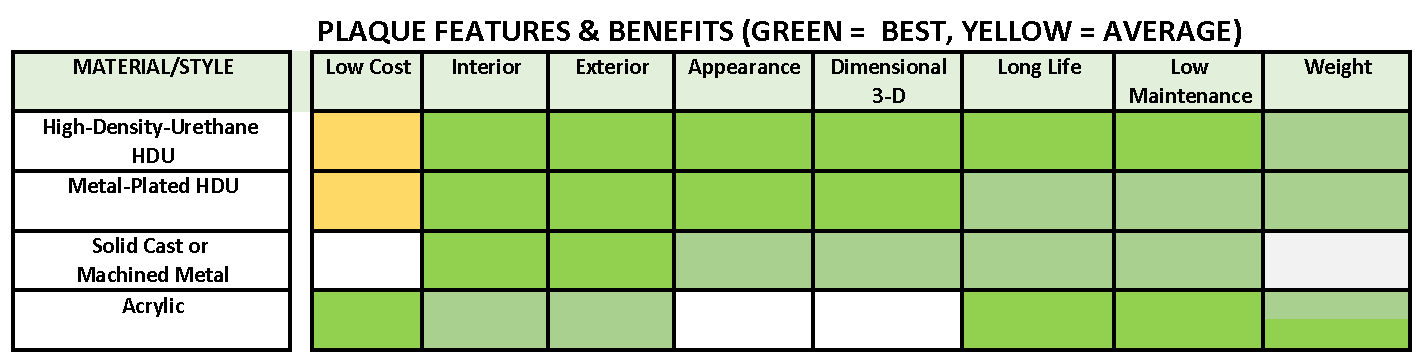

3. SIGN MATERIALS FOR SUBSTRATES

Because we make wall plaques with several different materials, it is useful to compare advantages and disadvantages of these substrate materials and styles in selecting a design for your plaque. These are shown in Table 1 below. Our 3-D bas-relief, 2.5-D multi-level raised relief, and engraved dimensional plaques are carved by our CNC routers from High-Density-Urethane (HDU) and wood (usually Cedar or Redwood, but sometimes Mahogany, Oak or Maple). For painted and metal-plated signs, HDU is the usually the best choice because of its lower prices, long life and minimum maintenance. Wood is selected when a stained, rather than painted, appearance is desired, but it has higher prices. We also offer solid cast and precision machined bronze and aluminum 3-D bas-relief, 2.5-D raised flat relief, and etched wall plaques and signs. Our least expensive plaques are flat (2-D) acrylic or PVC plaques with digitally printed giclee vinyl artwork and text.

> Table 1 - Comparison of Different Materials Used as Substrates for Wall & Podium Plaques

High-Density-Urethane (HDU)

High-Density-Urethane (HDU) is a great material for carving 3-D and 2.5-D dimensional plaques and signs. We make over 4000 HDU plaques and signs each year. We buy premium-grade Precision Plus HDU from Coastal Enterprises, in Orange, CA. We always use 20 lb/ft3 HDU, a higher density which is 40% stronger than the 15 lb/ft3 density HDU most other manufacturers use. It has a closed cell structure, and will not absorb water. It will not crack, rot or peel. It can be precisely cut, carved and sanded without splintering or chipping, because it has no grain structure, so small intricate features can be carved that would be difficult to carve in wood. If you want a beautifully detailed and precisely painted carved plaque, HDU is the material to use. Although not a consideration for indoor plaques, but highly relevant for outdoor plaques, HDU lasts up to 5 times longer than wood in outside applications, and is especially robust in severe environments of rain, snow, ice and high humidity such as coastal areas.

HDU plaques are either painted or metal-coated; they cannot be stained. However, they can be made to look like wood by employing a sand-blasting process using a wire frame, which produces a wood-grain type of surface which can then be painted with an airbrush to look very much like wood. HDU plaques are typically 1 inch to 1.5 inches thick for smaller plaques and 2 to 4 inches thick for large plaques. You can view over a thousand HDU plaques on this website.

Our HDU plaques are described in more detail in two subsections in this STYLE section: painted plaques, and metal plaques. These can be viewed by clicking on these names listed horizontally under the gold masthead above.

Fig 5 - The three basic materials we use for our Wall Plaques - High-Density-Urethane, wood (Mahogany, Redwood, Cedar, Walnut, Maple and Oak), and metals (bronze, brass, copper, nickel-silver, aluminum, 24K gold, and sterling silver)

Wood

About 30% of our plaques and signs, over 1500 each year, are made from solid hardwoods and softwoods , primarily Cedar and African Mahogany for indoor plaques and Western Red Cedar and Redwood for outdoor plaques and signs. We also make indoor wall plaques from hardwoods such as American Cherry, Black Walnut, Alder, Maple and Red Oak, or any other species of wood readily available. We obtain our wood panels from Forest Wood Products, a large manufacturer and mill of premium wood products. They cut and edge-glue under pressure strips of premium grade, kiln-dried, vertical grain, knot-free Cedar, Redwood, Mahogany. Walnut, Maple, Oak and Cherry into smooth-surfaced larger panels which are then planed flat and smooth before delivery to us. We then take these flat smooth panels and cut them into sign shapes, and then carve them in 3-D , 2.5-D, or engraved relief on one of our three 5 ft x 10 ft router/carver tables. Nearly all of our wood signs are stained (or left their natural color) and clear-coated, rather than painted. Some that are dark stained have V-carved engraved text, which can be 24K gold or silver leaf gilded to give an elegant look.

We rarely paint the entire surface of our wood plaques, instead we select HDU for fully painted plaques. HDU is less expensive and carves cleaner and more precisely because it has no grain structure like wood does therefore does not splinter. However, we do make many wood plaques with some areas stained and other areas painted. Wood plaques can be stained, painted or gilded with gold or silver leaf, but they cannot be metal-coated.

Wood plaques are typically 1 to 2 inches thick and weigh more than HDU plaques, but weigh a lot less than cast metal plaques. Over 300 wood plaques are shown on this website.

Our wood plaques are described in more detail in our wood plaque section. This can be viewed by clicking on this name listed horizontally under the gold masthead.

Solid Cast Bronze and Aluminum

We also sell 3-D and 2.5-D solid cast bronze and brass plaques. We design these but have an outside foundry cast them. These are about 5 times as heavy and cost 3 times as much as bronze or aluminum-plated HDU plaques, but they will last hundreds or thousands of years and are the only choice when bystanders can walk on them or rub them a lot with their hands. Cast metal plaques are typically 0.25 inches thick.

Sintra (PVC) Plastic

We make low cost 2-D plaques usingn 0..25 in thick Sintra (expanded PVC) cut-out substrates on which we adhere digitally-printed giclee vinyl appliques. These cost a small fraction of our other plaques, but look very good. Since we use high-resolution photos of our carved 3-D plaques, they look like 3-D plaques from a distance. They have flat surfaces, and cannot be carved in relief, so are not considered "dimensional". However, they can be cut in any size or shape. including irregular shapes with holes in them. These are typically 0.250 inches thick and are very light. Small ones can be mounted with double-backed tape.

Mahogany Veneer Wood

We also make low cost 2-D plaques using Mahogany venner wood, where a thin layer of African Mahogany is laminated to a MDO substrate, a technique also used to construct kitchen cabinets and furniture. We then adhere digitally-printed giclee vinyl appliques so the wood shows around the vinyl..These cost a small fraction of our other plaques, but look beautiful. Since we use high-resolution photos of our carved 3-D plaques, they look like 3-D plaques from a distance. They have flat surfaces, and cannot be carved in relief, so are not considered "dimensional". However, they can be cut in any size or shape. including irregular shapes .These are typically 0.250 inches thick and are very lightweight. Small ones can be mounted with double-backed tape.

4. PLAQUE SHAPES & SIZES

Our wall plaques can be ordered in any size from 10 inches high/wide to as large as 25 ft wide and 10 ft high.

Small & Medium Size Wall and Podium Plaques

Most of the plaques we make are round and have sizes from 12 inches to 36 inches in diameter. We can make a plaque in virtually any size from 10 inches to 10 feet in diameter, and because these are custom designed and carved, so do not have "standard" sizes, you can order nearly any size. However, we do not make very small (less than 6 inches) carved plaques with lots of detail (e.g. medallions , coins or badges), because of the limitation of our carving machines.

Our most popular size plaques are 24 and 18 inches. Typical sizes range from 12 inches and 16 inches for podiums, 16 inches to 24 inches for office and hallways, and 24 to 60 inches for lobbies, auditoriums, and court rooms. Plaques for a wall display of many Government or military seals (sometimes up to 30 plaques ) range in size from 14 inches to 24 inches. Plaques for outside locations such as on a monument sign or the wall next to a building entrance are typically 36 inches to 60 inches in size.

Large and Very Large Wall Plaques

We also make really large plaques & signs, up to 25 feet wide. Because we do not use molds, but custom carve every plaque, we can scale up the computer design to any size we can fabricate. Plaques up to 5 ft x 10 ft in size are carved from a single sheet of High-Density-Urethane ( which comes in 5 ft x 10 ft sheets) on our large table CNC routers, which also have a limit of 5 ft x 10 ft in size. We can make plaques larger than 5 ft x 10 ft by assembling multiple pieces together on an aluminum backboard or by using steel or aluminum internal or external framing which holds the pieces together with minimal visible seams. We often make very large plaques using this procedure; the largest plaque (it was considered a sign) we have made out of HDU is 17 ft x 9 ft . Single-piece plaques larger than 10 feet in their shortest dimension have to be shipped using a flatbed truck ; the largest single-piece plaque that can be shipped inside a standard box truck is 10 X 25 ft.

Plaque Shapes

We can make our custom plaques in any shape, including round, elliptical, rectangular, triangular, and irregular. However, the most popular shape is round, because most Federal and State government seals are round. Military plaques are made in the shape of their crests or insignia , e,g., shields and partial bordered round for the Air Force . Company plaques featuring their logo are often irregular , and coat-of-arms/crests have very complex and ornate shapes. You can order your custom plaque in any shape and we will cut it exactly as you have requested.

Chain-of-Command , Award and Recognition Plaques for Personnel

These custom wood and HDU chain-of-command and award boards and wall plaques are made in sizes from 24 inches to 120 inches wide. They can use photos and/or engraved brass plates with the names of personnel. They all have multiple people's names, ranging from few photos to several dozen brass plates . These are typically made of wood (African Mahogany, Redwood, Cedar and Oak) but we also make them using High-Density Urethane (HDU). These custom command and award plaques typically have several of the following features:

- Carved raised painted text for permanent positions (e.g., Commanding Officer, CEO, Champion, Donor, Awardee, etc)

- Picture frames with glass covers for easy to change-out photos

- Brass slide-in holders for engraved brass name plates which can be changed out easily

- 2.5-D multi-level or 3-D bas-relief carved and artist-painted or metal-plated (brass, bronze, aluminum or copper) seals, emblems, crests, insignia, coat-of-arms, or logos

- For small, very detailed artwork, printed giclee vinyl appliques mounted on carved pedestals

- Gold or silver leaf gilded letters or artwork

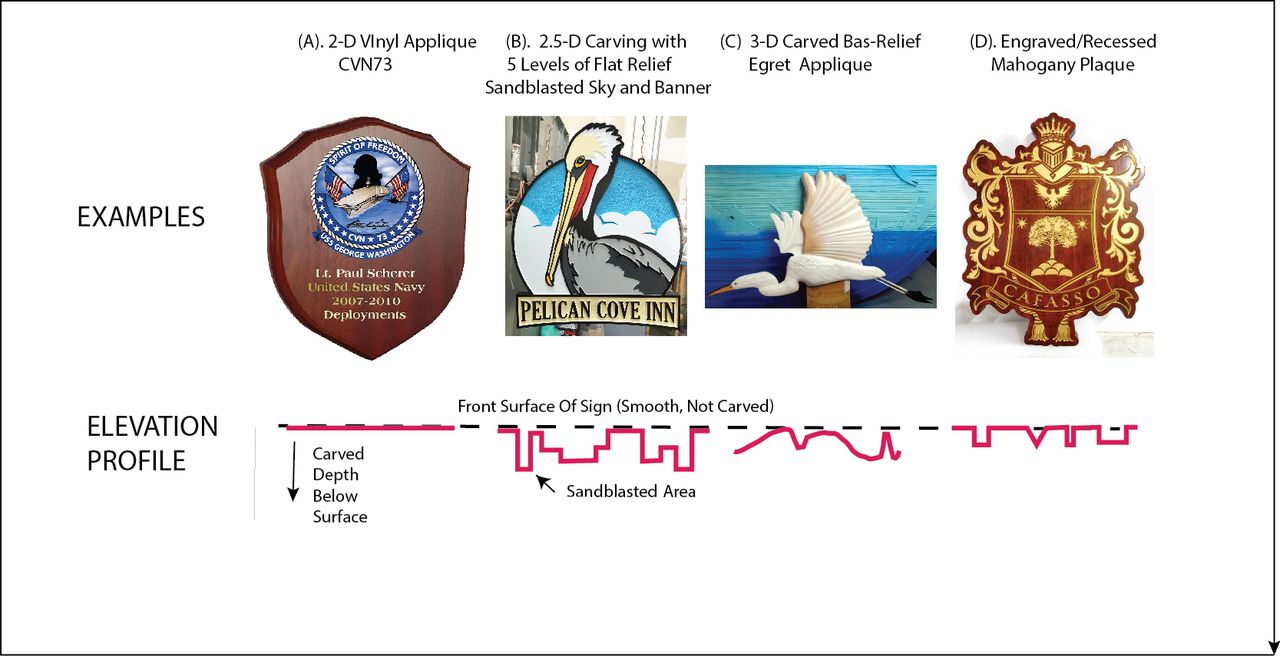

5. PLAQUE CARVING RELIEF

This section describes the 2.5-D, 3-D, and engraved carving techniques we employ to make our dimensional plaques. Fig. 6 below shows examples of each of these techniques. All our HDU and wood signs & plaques are first carved and cut out on one of our three 3-D large table (5 ft x 10 ft) Computer-Numerically-Controlled (CNC) routers/carvers. We do not use sandblasting by itself for primary carving of our wood and HDU plaques; it is too limited, too imprecise, and cannot create 3-D relief, multi-level 2.5-D complex surfaces, or engraved smooth surfaces. We do use sandblasting to create textured surfaces on backgrounds in selected areas, after the plaques has been carved on one of our routers. The Homeland Security plaque below has a white sandblasted background in sandstone texture.

Fig 6 - The three types of carved relief we create with our Computer-Controlled routers/carvers: 3-D bas relief, multi-level 2.5-D flat relief, and engraved/recessed relief

The computer programs that control the router bit tool paths can perform any of carving techniques shown in Fig. 7 below, or any combination of these 4 techniques on the same sign or plaque. About 60% of our dimensional plaques are carved in 2.5-D relief , 30% have some 3-D carving , and 10% are engraved. Our lower price plaques are carved in 2.5-D or engraved relief. Our 3-D plaques have higher prices because they take much longer to carve, and for multi-color plaques, they take much longer to paint because they require an artist brush to get the detail required over curved surfaces.

We have a few plaques each year which feature photos or very detailed artwork where we digitally print a decal on long-lasting vinyl (see the Mahogany plaque on the left in in Fig. 7 below), because hand-painting would be take too long and would not be as accurate; however these plaques have text, other artwork, and borders that are carved using one of the other techniques.

After we carve the plaques on one of our routers, we hand sand the plaques to produce a fine, smooth surface. Then, if sandblasted background areas are specified on the plaque, a rubberized sandblast mask is cut and installed on the plaque to prevent raised areas (such as text, raised artwork, and borders) from being blasted . The backgrounds can be blasted in either a sandstone texture or a wood grain texture (using a wire frame create the ridge pattern). They can also be left smooth and flat by eliminating the sandblast process. Only 20% of our plaques are sandblasted.

After hand-sanding and sandblasting, plaques to be painted are spray-painted with a thick prime coat, which smooths the surface and provides a good base for colored paint or metal-plating. Natural wood plaques do not have a primer coat, but are stained (or not) and clear-coated.

Fig 7 - Elevation cross-section profiles for carved 2-D, 2.5-D, 3-D and engraved/recessed relief plaques.

6. MATERIALS FOR SURFACE FINISHES

We use five general types of surface coating styles, shown in Fig 8 below, Most plaques can be made in any of these 5 styles (except HDU which cannot be stained). The least expensive is the printed applique; the most expensive style is gold leaf and stained wood.

Paint

We use the highest quality,fade-resistant, longest-lasting paints available for our plaques and signs. We use a special high-fill primer made by Coastal Enterprises for HDU, Matthews two-part polyurethane acrylic low-VOC MAP paint for backgrounds and large areas, and 1-Shot sign enamels for lettering and trim. All our signs are clear-coated twice with Matthews Polyurethane Acrylic (MAP) . Our paints are equivalent to automotive-type paints; and our paint is cured in a heated drying room. These paints cost $200/gallon, and are weather, UV and graffiti resistant. They are the finest sign paints available. They are far superior to house paints which most other manufacturers use, and last 3 times as long without fading. We can match any Pantone (PMS), Sherwin-Williams or Dunn-Edwards color. We also offer metallic gold, metallic brass, metallic bronze and metallic silver paints, which are lower price options to metal plating or gold or silver leaf gilding. See our Painted Plaques section on this website for more information on our paint techniques and many examples of our painted plaques. An example of a multi-color painted plaque is shown as the first plaque on the left in Fig 8 below.

Stained Wood

We exclusively use MinWax stains on our wood signs, or we can leave wood signs their natural colors. We can use any of the MinWax colors, and make them either light or dark by the amount of time we leave them on the sign or plaque before wiping, and also by the number of coats. Our experts in stains do an expert job, and our wood signs are have a quality equal to fine furniture. After staining and drying in a heated room for several days, we put two clear-coats of Matthews MAP on both indoor and outdoor wood plaques signs. We show a wide variety of wood stain colors and techniques in our Stained Wood Plaques section of this website. An example of a dark stained Mahogany plaque is shown as the second plaque from the left in Fig 8 below.

Metal-Plating

We make a over a thousand metal-plated HDU plaques and signs each year. We metal-plate only HDU signs, because HDU is impermeable, whereas wood is porous. Metal plating has a selection of bronze, brass, copper, nickel-silver, stainless steel, and aluminum metals. These are real metals deposited on 3-D and 2.5-D carved HDU signs using a proprietary cold cast process. After plating the entire front face of the sign with metal, we polish and buff high areas to a shine. We can optionally put patina on backgrounds to give greater contrast, or alternatively we can paint or hand-rub black or brown paint on the backgrounds and low-relief areas to give a dramatic visual effect that is very popular because it gives an antique look to the plaque. More information on dozens of examples of metal coated plaques is provided in the Metal Plaques section of this website. An example of a brass-plated metal plaque is shown as the middle plaque in Fig. 8 below.

24K Gold & Silver Leaf Gilding

We can gild both wood and HDU plaques with 24K gold and Sterling silver leaf. We can gild the entire front of the plaque, but usually we gild only a small fraction of the front face, 5% or 10%, typically the text, artwork and borders. We usually gold-leaf gild V-carved engraved text in our stained Mahogany plaques; the contrast between the dark Mahogany and the brilliant gold is very beautiful. Our artisans are highly skilled in this ancient art, because we gild over 200 plaques a year and have been doing so for over a decade. Gilding is expensive because of the price of the materials ($1400/oz for gold leaf) and the large amount of labor required to apply it and burnish it.

Gold leaf has an ancient heritage. It has been used to gild objects d'art and building architectural features for over 6000 years. King Tut's tomb contained many gold-leaf gilded wood artifacts, and many of the great palaces and cathedrals in Europe have gilded alters, ceilings and scrollwork. Many of the Faberge eggs were gilded with gold and silver leaf. For more information on our gold and silver leaf gilding, and many examples, please visit our webpages 24K Gold-Leaf Plaques and Sterling Silver-Leaf Plaques. An example of a gold and silver-leaf gilded plaque is shown as the second plaque from the right in Fig 8 below.

Printed Giclee Vinyl Appliques

We sometimes use giclee color photos and very detailed artwork printed on long-lasting vinyl and placed on a wood or HDU plaque as an applique. These are very high quality prints, equivalent to printing methods used for reproductions of fine paintings. These are digitally-printed using special inks put on long-lasting sign vinyl with high-end printers, the same way that colored pictures are made for cars, trucks, and buildings. We use this technique when the colored artwork is so detailed (like a person's photo) or so small we cannot carve it , even with a laser engraver, and artist-brush painting would be prohibitively expensive and time-consuming. These appliques are more accurate, look better, and last just as long as artist-brush painting. However, they are not dimensional, so must be applied to a flat smooth surface on a plaque. We often combine these appliques with carved, text, borders, and dimensional artwork. The Navy plaque page on this website shows several examples of how digitally-printed photos can be combined with carving techniques on wood plaques. An example of a plaque with a printed vinyl giclee image is shown on the right in Fig 8 below.

Metallic Surface Coating Options

We offer several alternatives if you want a plaque with a metal look, each with substantially different prices. For a gold look, the highest price option is 24K gold-leaf gilding, which has very expensive material (pure gold is $1500/ounce) and is very labor intensive (see prices listed in the Price Table at the bottom of the PRICE page). Polished brass-plated plaques have lower prices and are shiny, but its color is somewhat different than gold The lowest price option for a gold look is metallic gold or metallic brass paint They have approximately a gold color, but they do not reflect light like gold leaf or polished brass plating does.

For a silver look, we offer pure (0,996) silver-leaf gilding, polished metal plating of nickel-silver or aluminum or stainless steel, or metallic silver paint. The silver leaf gilding is the most expensive, then the metal-plating options , and metallic silver paint is least expensive. Aluminum plating is the shiniest of all of these options. For a bronze look, we offer polished or unpolished bronze plating or metallic bronze paint . The price of each of these plaque styles is given in the Price Table on the PRICE page.

Clear Coats

All our plaques, both for indoors and outdoors location, are clear-coated twice with Matthews Polyurethane Acrylic (MAP) clears. These are made in matte, satin, and gloss finishes. We use different formulations for painted, stained, metal-plated, and vinyl applique plaques. Matthews Clearcoats protect the plaques while enhancing their depth and vibrancy. Matthews clear coats provide unparalleled resistance to UV rays, moisture, harsh weather, impact, chemicals, and graffiti. These clear coats are applied with a spray gun in our paint spray booth. They can be satin, semi-gloss or gloss. All five of the plaques in Fig 8 below are given two protective clear coats.

Fig 8 - Plaques can Be Fabricated in One or More of these Five Surface Styles & Materials

7. METHODS FOR MOUNTING WALL & PODIUM PLAQUES

We can supply mounting hardware for any plaque. We employ several types of mounts, depending on plaque size and weight and the type of surface they are mounted on.

Small, Lightweight Plaques

Our smallest plaques, espeially lightweight HDU or giclée plaques, 14 inches or smaller, can be mounted directly on a wall using double-backed tape. There is no damage to the wall and the plaque is easlily removable. Another common method is to mount the plaque on a small nail or screw place in the wall, and mount it like a picture. We make a keyhole in the back near the top so the nail or screw cannot be seen. This method is usually preferred. The third method, which may do permanent damage to the wall and the plaque if the plaque is ever moved, is to place epoxy on the smooth back of the plaque and place it against the wall, pushing against the wall with some force.

Medium Size Plaques

These two methods are suitable for HDU or wood plaques up to 36 inches in size. The first, usually preferred method, is to use a Z-clip, a commercially available hardware item for mounting large pictures and plaques. This is a very thin aluminum french cleat that spreads the weight of the plaque over its area and the wall. Z-clips are made the width of the plaque, mounted near the top of the plaque. The matching piece is mounted on the wall with screws. The plaque is simply hung on the wall , by sliding the horizontal plaque piece of the Z-clip into the horizontal receptacle on the wall piece of the Z-clip. It is invisible to viewers of the plaque, and the plaque is easily removed by lifting it off the wall z-clip (however the wall piece would then be visible). See this link for further info. We have used long Z-clips to support plaques weighing over 800 lbs, and we highly recommend them for all but the largest plaques.

A second method is to use two keyholes in the plaque, which is hung on two screws, to distribute the weight of the plaque and ensure horizontal alignment. This method cannot be used for larger, heavier plaques like z-clips can.

Large, Heavy Plaques

For our largest plaques, 4 ft to 10 ft in size and weighing 300 to over 1000 lbs, we install stainless steel studs in the back of the plaque when they are fabricated. These studs can be as much as 3/4 inch in diameter and may protrude out the back of the sign 6 or 8 inches. Typically we install 5 or more studs depending on plaque size. These are screwed and epoxied into the thick sign back. For very heavy plaques, they may be welded to an internal steel frame. Holes are drilled into the wall using a template we provide we gives hole locations. The plaque is raised with a forklift or crane , the studs are coated with epoxy and inserted into the holes in the wall. If the wall material is thin or weak, or the plaque is very heavy, the studs may have to be inserted into upright or horizontal metal pr wood beams behind the wall, rather than into drywall or thin wood paneling. Fig 9 below shows an example of a very large plaque mounted on the wall of an entrance structure.

Fig 9 - Very large carved HDU Plaque with Internal Steel Structure and Threaded Studs for Attachment to Wall

PLEASE CONTACT US

The prices for different design styles for various size plaques is given on the PRICE webpage (click here or on PRICE in gold masthead) , listed by price code and plaque size. Or, you can fill out and submit our on-line Request a quote form. You can also call or email us for a price quote on a specific plaque. We will work with you to design and build the exact plaque you want. Our knowledgeable and helpful Customer Service Representatives, Christie, Regina, and Liz, will respond to your request promptly. Call us at 951-698-8484 or email us at info@artsignworks.com.

We would like to make your plaque, and we are confident that you will be pleased with it. We take great pride in every product we make for our valued clients. We offer a 2 year warranty on all our products, and our indoor plaques will last many decades without degradation.

WEBSITE NAVIGATION

You can go to another Section or Gallery page by clicking on an item in the pull-down menus in the gold masthead at the top of the page. You can search for a specific plaque type (e.g., "FBI" ) by entering the key word in the search box in the upper right of the gold masthead. You can view a list and use the navigation bar for all 24 Gallery types by viewing the silver box on the left side of the HOME page. You can view a description of different plaque styles by going to the plaque STYLE section. To request information, a design, a quote, or to place an order, click on the text (e.g., "contact ", " quote", " file" or " order") in the upper right of the gold masthead at the top of this page. All prices are given on the PRICE page in the gold masthead.

For more information on design options, prices and delivery times, please call us at 951-698- 8484 or email us at info@artsignworks.com, and our knowledgeable and friendly customer service representatives Christie and Regina will be pleased to help you.