Overview of Metal Plaques

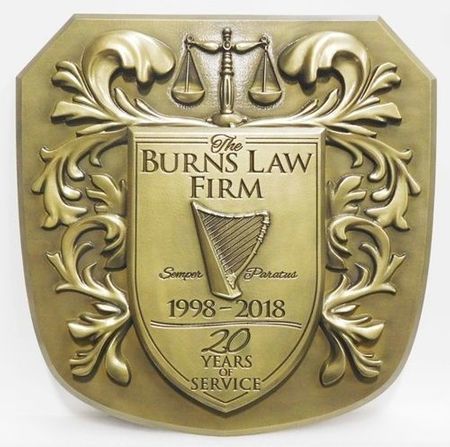

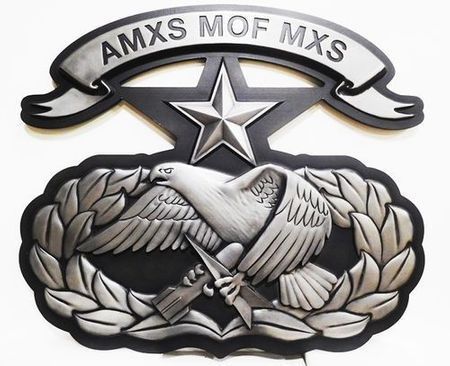

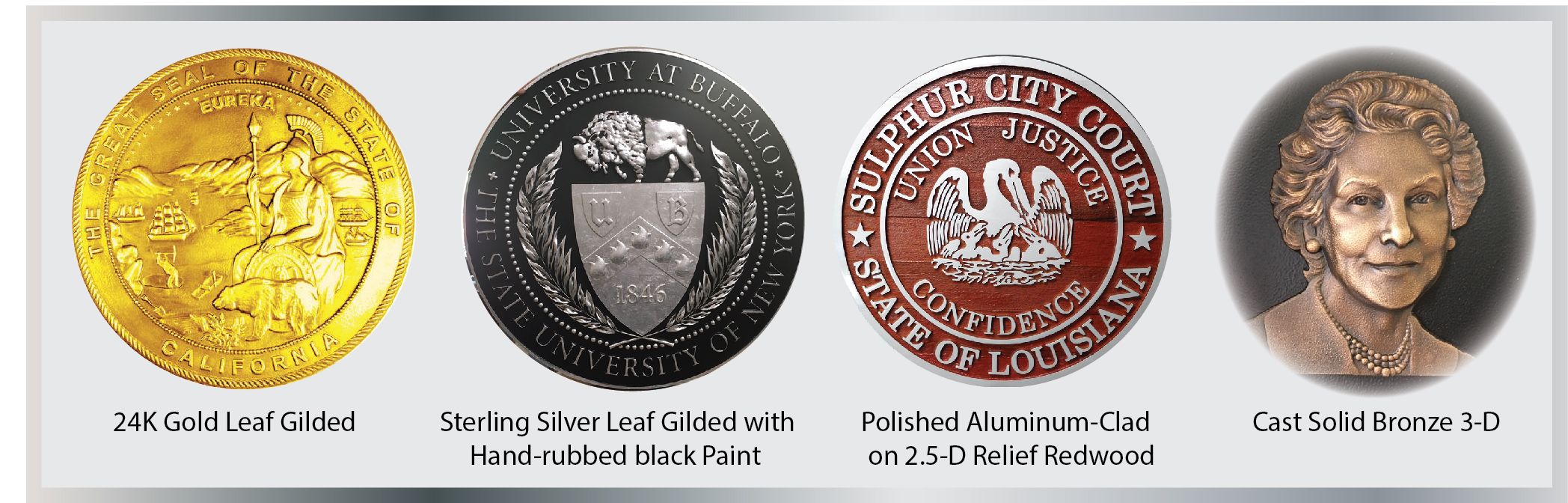

Fig. 1 - This picture shows the wide variety of styles of our dimensional metal wall plaques for Federal and State governments, courts , police, universities and clubs. Some plaques are carved in 3-D bas-relief, others in 2.5-D relief. Shown are bronze, brass, nickel-silver & aluminum -plated, and 24K gold-leaf and silver-leaf gilded plaques.

WELCOME TO OUR METAL PLAQUE SECTION (STYLE CATEGORY 1.2)

Welcome to our section describing our metal plaques, where we show over 200 examples of various types of metal plaques in seven photo galleries. This section describes only our metal plaques; our painted plaques are described in our Painted Plaques section, and our natural and stained wood plaques are described in our Wood Plaques section. We design and fabricate thousands of elegant and professional custom 3-D and 2.5-D metal plaques each year for courts, government organizations, the military units, police & sheriffs, universities, clubs, corporations, and homes. Each plaque is custom crafted by our experienced and skilled craftsmen and artisans. We use several different techniques to make these impressive and authentic plaques which retain their dignified beauty over many decades. These plaques are non-fading, moisture-proof, graffiti-resistant and long-lasting. This section, along with the 7 photo Gallery pages listed above horizontally under the gold masthead above, describes and shows hundreds of examples of these metal plaques.

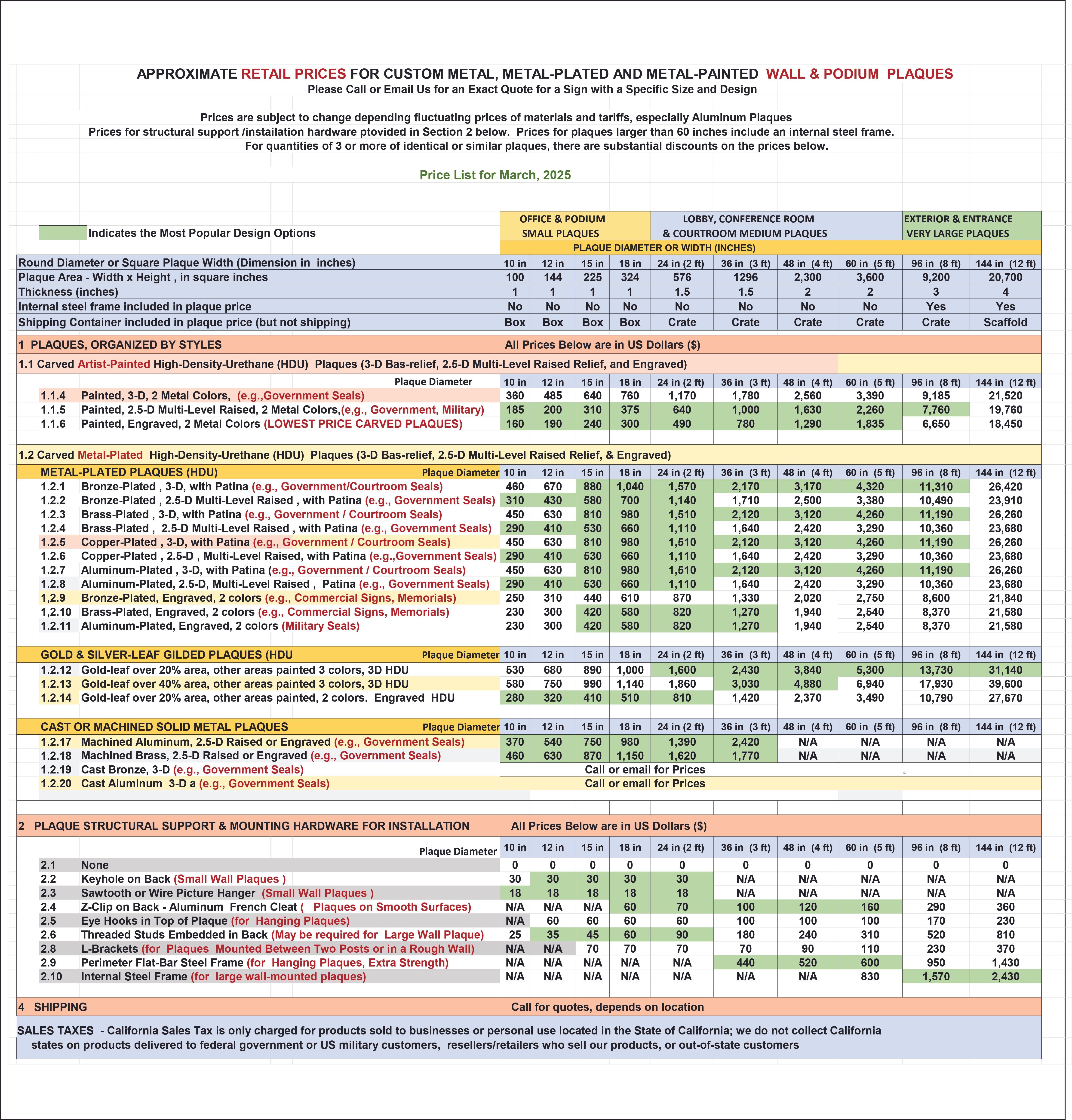

We offer seven styles of custom metal plaques, each with different prices:

Bronze-Plated (Style Categories 1.2.1 & 1.2.2)

Brass-Plated (Style Categories 1.2.3 & 1.2.4)

Copper-Plated (Style Categories 1.2.5 & 1.2.6,)

Nickel-Silver and Aluminum-Plated (Style Categories 1.2.7 & 1.2.8)

24K Gold-Leaf Gilded (Style Categories 1.2.9, 1.2.10., 1.2.11, & 1.2.12 )

Pure Silver-Leaf Gilded (Style Categories 1.2.13, 1.2.14, & 1.2.15)

Solid Cast Bronze & Aluminum (Style Category 1.2.16, 1.2.17, 1.2.18, & 1.2.19 ).

PRICES OF DIFFERENT STYLES

The lowest price plaques are painted with metallic paints, which included metallic gold, silver, copper, bronze, brass , aluminum, rusted steel and chrome. These have similar hues of metal plated and solid metal cast or precision machined plaques, but cannot be polished and do not have the reflectivity and sheen of polished metal. However these are very popular because of their lower prices.

Our retail prices for metal painted plaques are given in Section 1 in Price Table 1 below. Our prices for metal-plated plaques (High-Density-Urethan plaques coated with real metals in a cold-casting process) are provided in Lines 1.2.1 through 1.2.11 in Table 1 below. Gold-leaf gilded plaque prices are given in Lines 1.2.12, 1.2.13, and 1.2.14. Solid metal cast or precision machined plaque prices, which are the highest, are given in 1.2.17 and 1.2.20.

There are many ways of installing a plaque on a wall or podium, ranging from a keyhole hanging on a nail or screw for small wall or podium plaques to multiple threaded studs installed in the back of the plaque and inserted into holes drilled in the wall. Very large plaques (greater than 5 ft in diameter ) must be fabricated from multiple pieces of HDU joined together mounted on an internal steel structure. Large solid metal plaques are very heavy and may require structural strengthening the wall they are installed on. The metallic painted and metal-plated HDU plaques, even large ones, generally do not require reinforcement. Examples of large plaques (3 to 16 ft in diameter) are given in our Large Plaques (click link) section on this website.

The prices for these various methods of installation and structural support are not included in the plaque prices in Section 1 but are provided in Section 2, lines 2.1 through 2.10, in the Table below.

In the PRICE table below, plaque types are listed by Style Category and several plaque sizes. 3-D plaques have higher prices than 2.5-D plaques because of the additional labor and time to carve, plate and polish them. Cast solid metal plaques, especially custom 3-D plaques, have the highest prices , with gold and silver-leaf gilded plaques having lower prices. Metal-plated brass plaques have the lowest prices of our real metal plaques; our metallic painted faux-metal plaques (see paragraph below) have even lower prices, These are described in our 3-D Painted Plaques and 2.5-D Painted Plaques sections. Fig. 1 above and Fig. 2 below show examples of these different styles of metal plaques.

>

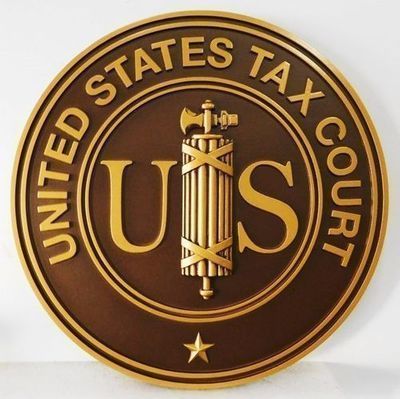

We have another option for clients who want metal-looking plaques but who do not want the expense of real metal plating. We can paint our 3-D and 2.5-D carved plaques with Matthews or 1-Shot gold, silver, bronze or brass metallic paint, which provides the colors of real metals but not the shine and reflections that only real metals can give. These plaques are only about 60% of the price of our metal-coated plaques, and many clients select these, including the US Tax Court, for which we made 18 plaques, and the Superior Court of California in Los Angeles, for which we made 24 plaques. For examples and photos of these metallic painted plaques, please visit our gallery Two-Color Painted Plaques page. You can call Christie, Regina or Liz at 951-698-8484 to discuss these various options or you can email us at info@artsignworks.com to get more information, to describe a plaque you want made, or to get prices.

Table 1 - Retail Prices of Various Styles and Sizes of Metal Wall & Podium Plaques

Fig. 2 - The picture above shows examples of 24K gold-leaf gilded, Sterling silver-leaf gilded. aluminum-clad Redwood, and cast bronze plaques.

DESCRIPTION OF DIFFERENT METAL PLAQUE STYLE FABRICATION TECHNIQUES

We make most of our metal plaques & signs by first carving ultra High-Density-Urethane HDU (density of 20 lb/ft3) in either 3-D bas-relief or 2.5-D flat relief (for all techniques except except for solid bronze or aluminum cast plaques). We have five different methods to fabricate a metal plaque or sign, one for each style, which are described below.

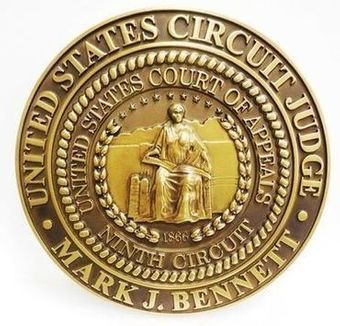

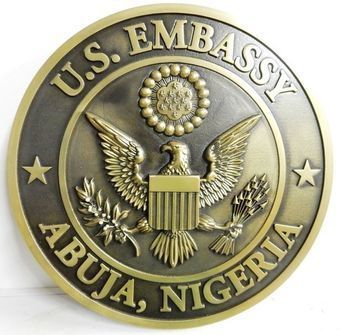

Fig. 3 - The picture above shows examples of bronze, brass, copper, and nickel-silver plated plaques.

METAL PLATING. We spray on a coat about 1/60th of an inch (10 to 15 mils thick) real metal particles (you have a choice of bronze, brass, copper, nickel-silver/German silver, stainless steel, or aluminum) imbedded in a binder over the entire plaque. We may then optionally paint a dark patina or dark paint (usually dark brown or black) on the background to enhance contrast, and then polish and burnish the metal plating first by machine and then by hand, to make some areas shiny. This technique is available for both 3-D and 2.5-D plaques.

Our metal-plated plaques and signs have advantages over molten metal cast bronze or brass (solid) metal plaques, because they cost about 1/3 as much and weigh about 1/5 to 1/10 as much. These metal-plated HDU plaques have the same appearance as cast bronze, brass, copper or aluminum, and they will last 30 years or more, for both exterior and interior applications, if people do not walk on them or rub them. They are completely waterproof and the metal gives a hard metal veneer over the HDU substrate The HDU substrate itself about the same density as Cedar or Redwood (20 lb/ft3). The metal veneer is about 12 mils thick (1 mil = 0.001 inch), 10 times thicker than electro-plating, and forms a very hard, protective, weather and UV resistant shell. All our metal-coated products are polished first by a buffing machine and then by hand with a buffing cloth to a high luster. This takes our craftsmen many hours.

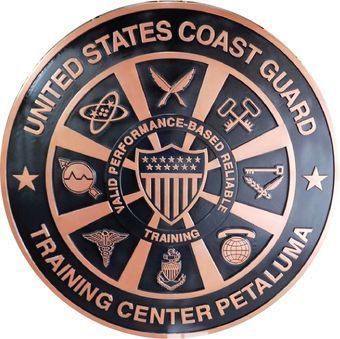

Fig. 4 - The picture above shows samples of brass, bronze, aluminum and copper-plated plaque finishes. They are all polished.

Fig. 5 - Another photo of samples of polished brass, bronze, aluminum and copper-plated plaque finishes, shown in 3-D relief.

The metal-plated background areas can be covered with either a patina to provide contrast and give the effect of age, or they can be painted. The patina is not perfectly uniform (it has very light non-uniformities in shade, i.e., slight blotchiness), because of the difference in chemical bonding, temperature, etc. to the metal surface. Every plaque will look slightly different. This minor unevenness gives it a very authentic, antique look. We can also paint the metal backgrounds with a flat or satin black or dark gray paint to give a very even, new look that provides a higher contrast between the background and text & artwork than patina does. Any of our metal-coated plaques can have either a patina or painted background. After the bright metal surface is polished and the background patina or paint is applied, we can coat the plaques with either a satin or gloss clear coat. The gloss is shiny and reflects light specularly whereas the satin finish will reflect light diffusely.

Four examples of metal-plated plaques (bronze, brass, copper, and nickel-silver) are shown above in Fig. 2. Fig 3 below shows the finish quality for four of the metals, when the plated HDU samples are polished and buffed. Each metal is described below, along with its heritage. You can click on the gold underlined text to go to the photo Gallery page for that metal, or click on an item in the horizontal list below the gold masthead to see that Gallery page.

Bronze. We make many plaques using bronze as the plating metal. Bronze is an alloy consisting primarily of copper, with about 12% tin and small amounts of other metals such as aluminum, manganese, nickel or zinc. The archelogical period where bronze was the hardest metal in widespread use is known as the Bronze Age, which began in Western Eurasia began about 4000 BC., Bronze was used extensively in Europe and China in ancient times for weapons, armor and tools, but it was eventually replaced in most applications by iron around 1300 B.C, ushering the Iron Age. Bronze is commonly used today for statues, plaques, jewelry, and other decorative items. Durable and classically beautiful, Bronze possesses all the physical properties of solid cast bronze yet its composite matrix gives it the added benefit of being anti-corrosive. An example of 3D bronze-plated plaque is shown on the right.

>

Brass. Brass is the most popular metal for plating our plaques, probably because it is bright and shiny and has a gold-like appearance. Brass is a metallic alloy that is made of copper and zinc. In antiquity, it was polished and used for mirrors. It is extensively used today for military and police insignia and badges, as well as many industrial applications. It is also used for architectural features on buildings such as domes, where it gives the appearance of gold when illuminated by the sun. Our brass plating is indistinguishable from solid, foundry-cast brass . An example of 3D brass-plated plaque is shown on the right.

>

Nickel-Silver (German-Silver). We use Nickel-silver, sometimes called German-silver, to plate many plaques each year. Nickel-silver is a copper alloy with 60% copper, 20% nickel and 20% zinc. Nickel silver is named for its silvery appearance, but it contains no elemental silver. The name "German silver" refers to its development by 19th-century German metalworkers in imitation of the Chinese alloy known as paktong (cupronickel). Nickel-silver was first known and used in China. It became known in the West from imported wares called paktong (Cantonese), literally "white copper", for which the silvery metal was used to imitate sterling silver. It formed an ideal, strong and bright substrate for the plating process. With our cold-sprayable plating application, Nickel-Silver plating is indistinguishable from foundry-cast nickel-silver and is an impressive silvery metal veneer on our High-Density-Urethane (HDU) plaques. An example of 3D German-silver plated plaque is shown on the right.

Aluminum. Many of our plaques are plated with aluminum, which gives them a shiny, silvery finish when polished and buffed. Aluminum is more reflective of light than nickel-silver, which has a duller, more diffuse finish. Aluminum is the 13th element, the most abundant metal in the Earth’s crust. It has a low density and is lightweight, strong and corrosion resistant. Aluminum was once considered more valuable than gold, Napoleon gave his most honored banquet guests aluminum utensils, while the others were given gold utensils. Aluminum is used extensively in buildings and architectural features. The apex of the Washington Monument is made of aluminum. Our aluminum plating possesses all the characteristics of foundry-cast aluminum, including texture and finish, and is indiscernible when compared to the solid cast or machined metal. An example of 3D aluminum-plated plaque is shown on the right.

Copper. We can plate any plaque or sign with copper. It is a soft, malleable, and ductile metal that has a reddish-orange color. Copper was discovered in the Middle East around 9000 BC, and is the oldest metal discovered by man. It was the first metal to be smelted from its ore, c. 5000 BC, the first metal to be cast into a shape in a mold, c. 4000 BC and the first metal to be purposefully alloyed with another metal, tin, to create bronze, c. 3500 BC. Copper was named after Cyprus, the principal mining place in Roman era (Cyprium), Copper is mentioned in the Bible: "Men know how to mine silver and refine gold, to dig iron from the earth and melt copper from stone" (Job 28:1–2). Copper is used in buildings, usually for roofing, and oxidizes to form a green verdigris (or patina). Copper is sometimes used in decorative art. Copper plating is indistinguishable in surface appearance from solid cast copper.

>

24K Gold Leaf Gilding. We gild by hand the surfaces of usually some but sometimes all areas of a plaque with 24K gold leaves, and then burnish the surface, which is a technique used by ancient Egyptians 3000 yrs ago (King Tutankhaman's artifacts were gold-leaf gilded) and used for thousands of years on architectural features and objects d'art in palaces and cathedrals. Gilding consists of applying small (3.5 inches x 3.5 inches) extremely thin rectangular leaves of pure gold to the surface to the plaque's surface using sizing. Excess leaf is cut off, and a protective clear coat is applied over the leaves. We often gild V-carved engraved letters, borders and artwork in wood or HDU substrates with 24K gold-leaf, leaving the backgrounds stained or painted. This technique is available for both 3-D and 2.5-D plaques. An example of a gold-leaf gilded plaque is shown on the right.

>

Silver Leaf Gilding. We gild by hand the surfaces of some areas of a plaque with pure (99.6%) fine silver leaves, and then burnish the surface, in a manner very similar to that of gold leaf described above. We can gild backgrounds, V-carved engraved letters, borders and artwork in for either wood or HDU substrates, or the entire plaque. This technique is available for both 3-D and 2.5-D plaques. Silver leaf must be sealed with two coats of Matthews polyurethane acrylic clear coat, or it will tarnish due to oxidation. An example of a silver-leaf gilded plaque in shown on the right.

Aluminum Cladding & Aluminum/Steel Sheet Signs. We cut out patterns of letters, borders or artwork from very thin sheets of aluminum, and mount them on wood or HDU text or art raised above the backgrounds, which has been carved out by our CNC router. We also cut out aluminum and wrought iron outline signs from 1/8 to 1/4 inch thick metal sheets with our water jet cutter, sometimes cutting out openings for either the letters or the backgrounds around the letters or art.This technique is available for 2.5-D plaques only (not 3-D). An example of an aluminum-clad plaque is shown in Fig. 2 above (second plaque from right).

Solid Cast & Machined Bronze and Aluminum. We also offer solid cast and precision tooled custom and standard bronze and aluminum 2.5-D and 3-D plaques, which we get wholesale from a professional foundry. These are the only plaques we do not fabricate in-house; we design them but have a foundries who we partner with which actually cast or machine them. For casting, they first require a 2.5-D or 3-D computer design, which is used to drive a CNC router to carve a foam replica. This replica is then used to create a sand mold, and molten bronze or aluminum is then poured into the mold. After the plaque is cooled, it has any rough edges ground off, and it is polished and coated. Background areas can be given a patina or can be painted. An example of an cast bronze plaque is shown in Fig. 4 (right side). You can also order precision tooled bronze, brass, or aluminum 2.5-D plaques. These are precisely machined out a sheet of bronze, brass or aluminum, and can have a variety of shapes, custom artwork, flat relief levels, surface finishes, and colors.

We sometimes combine two of the above techniques together on the same plaque (but in different areas), i.e, we often gold-leaf a small area of a brass-plated plaque to hi-lite artwork or raised text, so as to provide visual interest in key areas of the plaque. Many of our original and creative 3-D designs are true works of art.

HOW TO CONTACT US

The prices for each of these different styles for various size plaques is given on the PRICE webpage (click here or on PRICE in gold masthead) , listed by style and plaque size, under the general metal plaque Style Category 1.2. Or, feel free to call or email us for a price quote on a specific plaque. We will work with you to design and build the exact custom plaque you want. One of our knowledgeable and helpful Customer Service Representatives, Christie , Regina, or Liz, will respond to your request promptly. Call us at 951-698-8484 or email us at info@artsignworks.com. Or, you can fill out and submit our on-line Request a Quote form. We take great pride in every product we make for our valued clients. We offer a 2 year warranty on all our products, and our indoor plaques will last many decades without degradation.

WEBSITE NAVIGATION

You can go to another Section or Gallery page by clicking on an item in the pull-down menus in the gold masthead at the top of this page.

You can search for a specific plaque type (e.g., "FBI" ) by entering the key word in the search box in the upper right of the gold masthead. You can view a list and use the navigation bar for all 24 Gallery types by viewing the silver box on the left side of the HOME page. To request information, a design, a quote, or to place an order, click on the text (e.g., "contact us", "get a quote", "send a file" or "place an order") in the upper right of the gold masthead at the top of this page. The prices for each of these different styles for various size plaques is given on the PRICE webpage (click here or on PRICE in gold masthead) , listed by price code and plaque size, under Style Category 1.2.

For more information on design options, prices and delivery times, please call us at 951-698- 8484 or email us at info@artsignworks.com, and our knowledgeable and friendly customer service representatives Christie and Regina will be pleased to help you.